Commercial Desiccant Units- When is it best?

Unlike Industrial Desiccant Dehumidifiers which are very expensive and in some cases inflexbile, a Commercial Grade Desiccant unit delivers the best performance for many applications without overdoing it which meets the application more precisely in simplicity and cost.

– Low Dewpoints are great for Chilled Beam Applications as if the humidity is reduced, the risk of condensation is reduced as well. WHY? Because a lower dewpoint means a lower relative humidity and that allows more room for error (45 RH to 100% RH is better than 55 % RH).

– Desiccant Units are more Efficient. The silica gel of the desiccant wheel is “thirsty” vs a compressor in a hot-gas reheat system which needs to work harder (higher head) delivering lower discharge temperatures. WHY? Head is the difference between the ambinet temperature that the compressor is rejecting to verses the discharge temperature, typically lower to “overcool”. That is why desiccant units are eligible for NJ Smart start rebates.

– Commercial Desiccant units are perfect for Freezer Doors and Display Cases in Supermarkets. WHY? The lower dewpoint allows the air to not condense and freeze on the door when it is open.

– Get more capacity from the equipment that is already there. WHY? Again, direct expansion equipment (DX) performance will improve with reduced head pressure and removing latent capacity will achieve this. The same unit with a lower entering dew point will result in a lower discharge temperature which leads to higher EER (because of the higher dry bulb delta T). This can also be acheived with a chiller: increase the chilled water temperature to increase the kw/ton and as you get more MBH.

– Packaged DX equipment can typically deliver 55F dew point; Industrial can get to 10F or even lower (with a high price tag). The commerical desiccant unit we offer is about 40 F dew point.

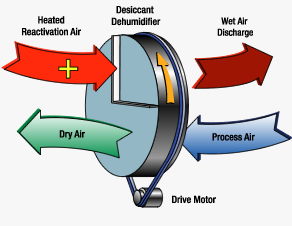

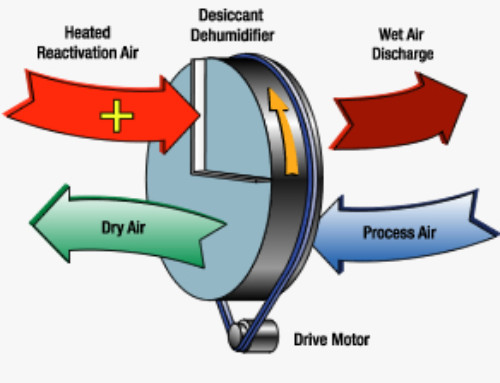

How It Works:

Unlike using a cooling coil to remove the moisture, a desiccant wheel is used to pull the moisture out. The wheel is essentially warmer and dryer than the air it’s treating (known as “process air”) and will literally pluck the grains out. It is a very efficient way of removing moisture and is used in applications where the cooling coil cannot be used (ie, ice rinks are cold enough that the condensate coming off the coil would literally freeze on the coil making the coil ineffective).

In order to keep the desiccant wheel warm and dry, it needs a regeneration process once it has retained the process air’s humidity and this requires heat. For highly industrial processes, the heat source would be an electric coil, steam coil or direct fired burner. While you can see a performance of 7.8% RH in the summer or lower (think leaving air of 75db/49 WB for with an entering air of 95/75), for commercial applications, it is a very expensive first cost as it will require a post cooling coil to bring very warm, bone dry air (125F+, ~2%RH) down to the required temperature.

For a commercial desiccant unit, a small refrigeration circuit is used to essentially precool the air which reduces the entering air dry bulb but increases the RH. The wheel removes the moisture and slightly heats the air in the process (but the air was precooled!) and this results in dry neutral air (75 DB, 40 dew point/~30%RH). The condenser coil in this case becomes the heat source to regenerate the wheel. This is a very effective means to dehumidify.

When the space humidity levels are lower, there is a lot of advantages- comfort, operating costs, indoor air quality. Please Contact US 973-536-2220 for an unbiased solution to all of your humidity needs!

Additional Articles: THE GOOD BETTER BEST OF DEHUMIDIFICATION