Call 973-536-2220 For Assistance on Your Project!

NOVELAIRE:

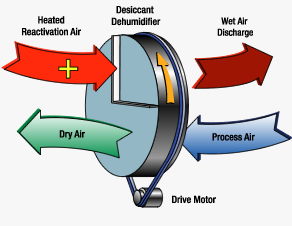

Desiccant Dehumidification

Energy Recovery Wheels

Novelaire builds competitive high quality built to order commercial grade desiccant dehumidifiers.  The desiccant wheel is very efficient and effective at removing moisture from the air. While this approach is associated with highly industrial processes (10 grains, or example 70F,10% RH)), commercial grade is more in the range of 20-40 grains (such as 70F, 40%RH). Units come in small and large sizes and can be recirculating or 100% OA with energy recovery. In some cases these units qualify for NJ energy rebates.

The desiccant wheel is very efficient and effective at removing moisture from the air. While this approach is associated with highly industrial processes (10 grains, or example 70F,10% RH)), commercial grade is more in the range of 20-40 grains (such as 70F, 40%RH). Units come in small and large sizes and can be recirculating or 100% OA with energy recovery. In some cases these units qualify for NJ energy rebates.

While NovelAire has some electric regeneration units, their power of offering is their DEX/DX Technology! Utilizing a standard refrigeration cycle, the DES/DX technology uses the evaporator coil to precool the air and the warm condensing coil to regenerate the wheel. The result is a single package delivering neutral 40F dewpoint air with unbelievable efficiency. Our DES/DX300 is only 30″x40″ x20″ and can pull 8.5# water per hour. Installation takes just a few hours with 4 flex connections, single phase power connection, drain and humidistat. It has saved the day in Gyms, Labs, Preventing Mold, Warehouses and More. The DES/DX technology is available up to 15000 cfm as a complete packaged unit (again, with winter heat, filtration, etc)

We also can help you in an “Industrial” process requiring greater dehumidification power (10 grains!). In this case, we would steer your project into a more traditional active desiccant with more robust regeneration. To achieve better dehumidification, we would use a gas heater (direct fired is most common, but indirect is available for class 100 spaces), steam heat, or electric heat. We can provide the package with Pre-cool and/or Post Cool as required.

Again, we can provide just the dehumidifier or an entire HVAC package for all the temperature and humidity control.

the internals of the DES/DX technology using the condenser to regenerate the desiccant wheel

Remember, Units can be Spot Dehumidifiers or Complete Packages!

NovelAire also is an OEM Manufacture of Energy Recovery Wheels using Molecular Sieve Technology.

Lower price wheels use a plastic material impregnated with a silica gel which will absorb the water vapor from the air and will expel the water with the force of an exhaust fan and the vapor pressure difference between the air paths. While this type of wheel is “fine” and well proven, its performance is inferior to the molecular sieve and there is a chance of smells transferring from the outside air inlet to the exhaust air outlet.

The molecular sieve uses a 4Å slit which allows only the water vapor to pass through. The material of the wheel itself is aluminium which is lightweight but more sturdy than the plastic wheel. The wheel rotor shall be constructed of alternating layers of flat and corrugated media.

We can offer a full cartridge including the wheel and drive to install in a new, retrofit or replacement HVAC Unit. If its a tight rig, we can offer the unit to ship in sections.

We can also offer full AHUs and Packaged units with wheels

CONTACT US!