Engineered Air Solutions takes pride in our knowledge and product offering for humidity control. While we have dehumidifiers, this article is about adding humidity. Here are the basics:

- Canister type: Probes in a plastic tube will arc and boil water at the probe.

- Pros: Low first cost, easy maintenance, modulating output, compact footprint

- Cons: Higher water usage, not good for precision, dependant on water quality, cost of replacement canisters

- Resistive type: Stainless steel barrel boils “pot” of water

- Pros: Lower maintenance cost, choice of city or tap water, modulating output, better reliability, better precision, especially in treated water applications.

- Cons: Higher first cost, time required for cleaning if city water is used

- Steam to Steam: Heat exchanger using house steam to create clean steam

- When gas fired boilers create steam, the chemicals in the water may not be appropriate to put in air. The clean steam heat exchanger will transfer the heat from the boiler loop to a loop that does not see those chemicals. Common in the medical field.

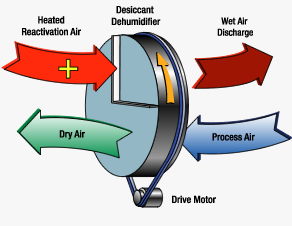

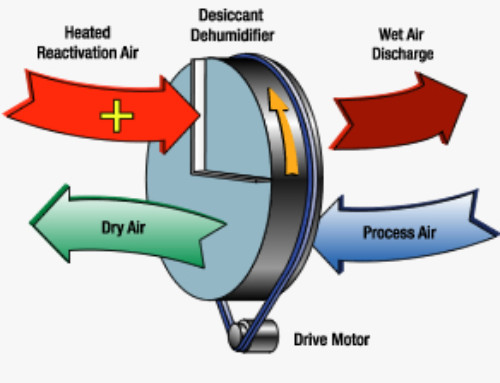

- Adiabatic Humidifiers: Using the heat already in the air, water vapor is mechanically introduced in the air stream. It will use the energy in the air to evaporate which cools the air. This is a different process than the above units which use a heat source to evaporate the water, keeping the air temperature constant. (ie, a canister will theoretically bring 70 degree, 25RH air to 70 degree, 50% air; an adiabatic humidifier will bring 70 degree, 25RH air to 55 degree, 55RH). Adiabatic “generators” use significantly less energy than the boiling type, but in some cases the energy comes from elsewhere. In other words, for comfort cooling, if the heating coil is discharging 95F, it may leave the humidifier at 75 which means in some cases, the heat source needs to be increased to achieve the same result as the boiling type humidifier. Low absorption required on jobs (i.e. 6”-36”) is not possible for adiabatic humidifiers in comfort cooling ducted applications.However, in high sensible applications such as Data Centers, the adiabatic process actually uses the extra heat to cool the space while increasing the humidity level. This lowers the run time of the compressors which saves significant energy.

- Ultrasonic: Uses high velocity discs in a pan of water to create a cool mist

- Pros: Perfect for 10-80# increments. Can be standalone without a fan or in an AHU. Great capacity control (no boil kill for makeup water)

- Cons:Treated water recommended (DI/RO, etc)

- Air/Water: Pressurized Air will convert water into a mist

- Pros:Perfect for 100#-500#, lower absorption distance than atomizing. Lower product cost than atomizing.

- Cons:Requires both air and water lines in application; Treated water recommended

- Atomizing: Uses high pressure water through a nozzle to create a cool mist

- Pros:Perfect for 1000#+ , single water line, lower power consumption than air/water

- Cons: Better for larger projects to be competitive