Call 973-536-2220

Engineered Air Solutions offers a complete line of dehumidification products to meet your application and budget.

Applications to consider for Dehumidification:

- High outside Air

- Pharmacuticals & Labs

- Water Treatment Plants

- Archival Storage and Product Protection

- Mold Abatement

- House Air for Chilled Beam Systems

- Indoor Pools (read our white paper- “remedy a cheap indoor pool hvac system!)

- Food Processing- Food Drying, Wash Down Areas

- Supermarkets

- Ice-Rinks

Unbiased white paper on the different types of dehumidification

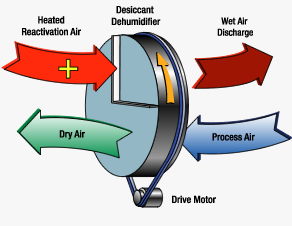

For over 80 years Bry-Air has been a leader in dehumidifying with a silica gel desiccant. As a global company with headquarters in Sunbury OH, Bry-Air offers industrial solutions to bring any amount of air at any inlet down to any humidity level. “0 grains or lower”. Precision can be utilized by modulating the regeneration heat source, bypass dampers or the wheel itself. Pre-Cool and post cool options are available. Regeneration can be achieved by using direct or indirect gas fired heat, house steam, or electric Heat.

Units can be a simple pre-engineered “Mini-Pac” or a built to order skid encompassing all the required particulars. Our DC series allows us to provide a module without the fan to be added to a custom air handler (existing or new).

Our VFB Series (300-30,000 cfm) is built with premium features including all welded aluminium construction, vapor proof gasketing, hinged access doors, optional primary heat and filtration, and more.

The Bry-Air Eco Dry system takes advantage of variable loads and maximizing energy consumption by varying the wheel speed, regeneration output and supply air flow to reduce the input kw by as much as 45% using its unique algorithms. This system is available on the VFB and DC series.

Novelaire builds competitive high quality built to order commercial grade desiccant dehumidifiers.  The desiccant wheel is very efficient and effective at removing moisture from the air. While this approach is associated with highly industrial processes (10 grains, or example 70F,10% RH)), commercial grade is more in the range of 20-40 grains (such as 70F, 40%RH). Units come in small and large sizes and can be recirculating or 100% OA with energy recovery. In some cases these units qualify for NJ energy rebates.

The desiccant wheel is very efficient and effective at removing moisture from the air. While this approach is associated with highly industrial processes (10 grains, or example 70F,10% RH)), commercial grade is more in the range of 20-40 grains (such as 70F, 40%RH). Units come in small and large sizes and can be recirculating or 100% OA with energy recovery. In some cases these units qualify for NJ energy rebates.

We also can help you in an “Industrial” process requiring greater dehumidification power (10 grains!). In this case, we would steer your project into a more traditional active desiccant with more robust regeneration. To achieve better dehumidification, we would use a gas heater (direct fired is most common, but indirect is available for class 100 spaces), steam heat, or electric heat. We can provide the package with Pre-cool and/or Post Cool as required.

Again, we can provide just the dehumidifier or an entire HVAC package for all the temperature and humidity control.

– Indoor Pools (read our white paper- “remedy a cheap indoor pool hvac system!)

the internals of the DES/DX technology using the condenser to regenerate the desiccant wheel

– Basements

– Chilled Beam (use for Primary Air)

– Schools

– Make Up Air to VRF, WSHP, PTAC’s

– Supermarkets

– Supplemental moisture removal

– Retrofits

Remember, Units can be Spot Dehumidifiers or Complete Packages!

NovelAir Provides Packages Upto 15,000 CFM with optional heat, filtration and more

ADDITIONAL TECHNICAL INFORMATION ON DESICCANT UNITS

Off The Shelf & Readily Available Units

MECHANICAL DEHUMIDIFICATION:

For systems where there is high humidity loads, but extreme low dew points are not needed and cost is an issue,mechanical dehumidification is likely your best choice. Many of our brands have this feature (Geo-comfort water source heat pumps, United Cool Air Indoor Packaged Units and Addison Outdoor and traditional split systems)

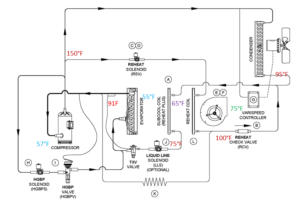

Use the Cooling Coil to wring the moisture out and allow the warm condenser air to reheat the air to neutral. This is known as Hot-Gas Reheat (learn more)

Addison brings dehumidification to a higher level by using a 2 step approach. A subcooling coil coming from the condenser line upstream to the cooling coil will be the first stage of reheat. The genius part of this first step is the refrigerant on its way to the evaporator is actually cooled by that subcooling coil, providing a lower dewpoint! Better performance and higher efficiency is the result. For an added step of reheat, a traditional hot gas reheat coil would be downstream of the subcooling coil.

Hot Gas Reheat can be on/off or controlled by a modulating valve. A humidistat would force the cooling on and enable the dehumidification cycle. In the case of modulating hot-gas reheat, a discharge setpoint would be enabled, and similiar to cruise control on a car which will accelerate/decelerate to maintain 55f, the unit controller will modulate the warm refrigerant to maintain a specific discharge air dry bulb.

Addison’s Premium Dehumidification utilizing a subcooling coil with Modulating Hot-Gas Reheat

WE ALSO HAVE PASSIVE DEHUMIDIFICATION USING HEAT-PIPE WRAPAROUND:

CONTACT US

973-536-2220; [email protected]