call 973-536-2220!

Just like every HVAC system, the VRF has its place as the choice for HVAC systems. They are quiet, flexible and efficient. And, as everyone knows there are things to consider as there are limitations to this type of equipment.

On the reverse cycle (heat pump), just like traditional systems there are limits to consider in terms of heat. While the unit can handle the ambient low temperature on the outdoor, there is a limit on the evaporator of how low the entering air is on the indoor unit. VRF systems are also somewhat limited in latent capacity in the summer. Therefore, additional components need to be considered for commercial applications where more outside air is necessary.

Considering how commercial spaces require a minimum amount of outside air, careful considerations must be met regarding inlet air conditions. (55-60F). On a 10F day, if you are bringing in 25% oa and maintaining 70 in the space, mixed air is about 52F; lower for 0F day.

The simplest thing to do is use a TUTCO electric heater. Units are available for Round duct and as well as rectangular and is made to order. TUTCO electric heaters can be single stage, multistage or variable capacity with SCR control.

While a slip in heater may get the job done in the winter, it does not address the summer and it will be an additional source of energy consumption which negates the overall system efficiency. This being said, a heat recovery (HRV) or energy recovery system (ERV) would be the better choice. These systems start at 50 cfm and can go to 20,000 cfm or more. For the sake of typical VRF systems, the most common cfm is between 150-500 cfm, typically.

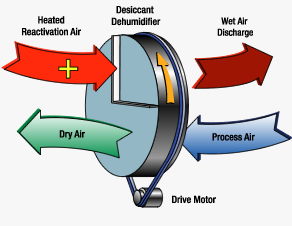

What is the difference between a HRV and ERV? Heat recovery units transfer the sensible heat; moisture content of the air is “wicked” by a desiccant integrated to the medium (energy wheel or enthalpy core) with energy recovery units. HRV’s tend to be less expensive and are easier to clean but for cooling capacities, energy recovery units may be the preferred means. On a winter day (design 0-10F depending on the bin hours you consider and the project location) you can get the cold winter air up to 50-60F; upon mixing return air there is no issue making the minimum inlet temperature required (25% at 50F + 75% at 70F =65F).

Another thing to consider is the HRV/ERV reduces the load to the mechanical by using the exhaust air to pretreat the outside air which effectively reduces VRF size and adds to its diversity safety factor.

Learn more with LIFEBREATH and TEMPEFF.

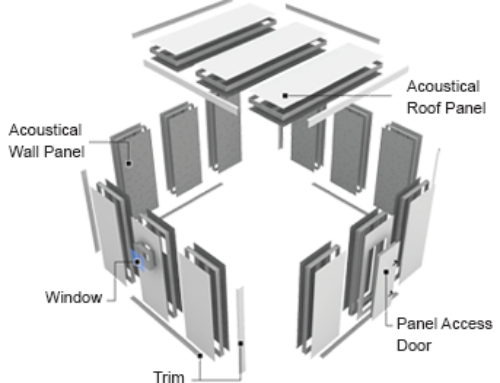

What if you want dedicated outside air but not directly feeding the VRF? An energy recovery packaged unit or DOAS unit would be required. It would have the capacity control for heating, cooling **and** dehumidification. Learn more with ADDISON

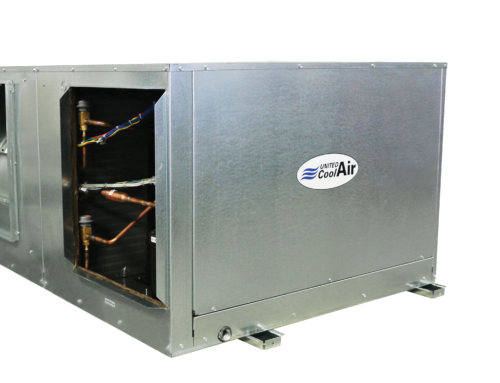

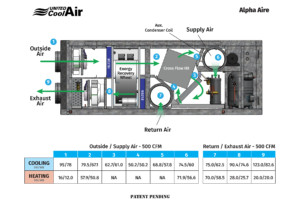

One thing to consider is United Cool Air’s Alpha Air System. At up to 500 cfm, this unit incorporates 2 heat exchangers and a compressor to provide full heating as a heat-pump (with no electric coil used or required), cooling and dehumidification 365 days a year using a small compressor. The first energy recovery wheel pretreats the air and the integral second heat recovery provides heat all year round- extra heat in the winter and free heat for dehumidification in the summer. The air coming out of this unit is completely independent of any system and will allow full diversity safety on the VRF as well as allows it to do only the space air. For the ultimate in comfort and energy efficiency this unit should be considered as does 3 separate functions in 1 horizontal or vertical cabinet. It also does n

ot require any additional ducting, power or controls in comparison to adding a heater to an energy recovery unit and an outdoor condensing unit. Alpha Aire Sales Sheet. Alpha Aire Engineering Guide.

As no 2 buildings have the same requirements, choices are required. The purpose of this piece was to highlight the different options. This is an overview, so please call Engineered Air Solutions for job specific details!

Additional info: