Things to Consider

While a large open “simple” box may seem simple, there are items to consider to meet the intent and installed budget for this kind of building. Unlike a typical residential or commercial space with 8-12 foot ceilings, it is not uncommon for warehouses to stock product up to 40 feet in the air.

To figure a load, one needs to consider the R value of the roof and walls (they are low compared to conventional spaces; R-11 for roof, R-5 for walls). Outside air is required (at .06 cfm/sqft in NJ). Dock doors need to counted and dimensioned. You may want to consider Air Curtains.

For design most spaces require heat only and the first question to be asked is how much? Is it only to keep the fire sprinkler heads from freezing? Is there a small handful of employees that you need to meet minimum heating requirements? For basic heat, it is common to set the setpoint at 55F; for comfort conditioning heating would be 65F in the winter, 75-78 in the summer.

There is a trend to keep employees happy in terms of comfort to eliminate personal turnover in manufacturing and distribution. In addition, there are products that are temperature sensitive, and that would require consideration of equipment.

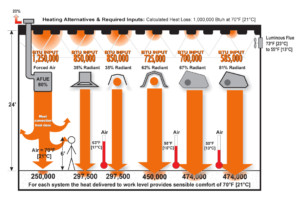

In all cases, with high ceilings warm air rising is an asset and liability. Asset- the warmer air will hover by the aforementioned fire sprinkler heads. Liability- people walking on the floor may not feel the heat. Keeping the warm air stratified forces the HVAC equipment to work harder, increasing the gas consumption.

Products to consider

For heating only and small spaces, unit heaters are available in electric, hot-water, and gas. While there are nozzles which can point the air down, these units should really be intended for basic heat (ie, no pipes freezing application) as the heat it produces will only hover up top.

For small and medium sized spaces, infrared heaters should be considered. Infrared heaters are available high intensity (ceramic squares) or tube heaters and are typically gas (or electric in limited capacity). Tube heaters can be straight run or in a U-tube. The magic of the infrared heaters is they beam the heat, so they can be mounted like a unit heater but the heat will make it down the space. This beamed heat will heat all surfaces so people will feel the warmth first, air secondary. For loading areas, when a dock door is open, all t

he warm air on a cold day will rush out, but people will feel the heat and the floors and product exposed to the infrared will produce warmth secondary as a flywheel effect as it has been collecting the rays. Any heat not converted into infrared would be thermal and would rise, allowing the fire protection to stay functional.

When laying out infrared heat you need to watch the “clearance to combustibles” which simply means the tubes themselves run well over 1000 degrees at the beginning of the tube and run down to

just under 300 at the end. You need to make sure the beam of heat is not hot enough to burn or cause product to catch fire. Clearance to combustibles can range from a few inches to 10 feet (or more in the high intensity version). As a rule of thumb, the higher the heater, the larger the path it covers, with a diluted output. With the tube type, being the 2 ends have opposite output one can lay out a hot side and have the next hot side laid near the low side of the previous tube to keep things consistent or use a U-tube so the hot end meets up with the cold end keeping the whole heat profile consistent. For high intensity heaters there is no exhaust, but you will need to make sure there is enough fresh air in the space as it will use oxygen (typically x cfm/sqft). Tube heaters typically have exhaust, and 2 heaters can share a common controller and exhaust. Tube heaters can also be tied to a BMS.

Tube heaters and unit heaters are great if you need to break the space up for multiple tenants or zone control. Should basic comfort levels be required but there is no budget for cooling, HVLS (high volume low speed fans- whitepaper) should be considered as 1 fan can up to 120 feet of floor and move 300,000 cfm (REF)

For larger spac

es, one can consider a central HV (Heating and Ventilating unit) which would be typically direct fired, 100% OA which would pressurize the space and that air would then be pushed out with louvers or exhaust fans. The burners would only come on days below 50F and being its direct fired, all the gas energy would convert to heat (near 100% efficiency). By pressurizing the space, the air through the space would have basic heat. These units typically use a single discharge head (not duct work) to keep the install cost low. Each H&V unit can run 2.0 Million BTU’s or more.

What if you need cooling? High-volume re-circulation is critical to effectively cool & dehumidify a big open space, and Air Rotation is often the most simple and effective method to provide air conditioning. An Air Rotation unit will utilize heating (steam, gas burners, electric, oil, hot- water, etc), cooling (Dx, Chilled water), humidification, dehumidification, special filtration, etc. The nominal height of the unit matches the nominal height of the building and will blow the air across 200-400 feet). The Return, mounted low, will pull the air back, creating a “rotation” as the name suggest. Better units will utilize an airfoil propeller fan which runs efficiently to match its design: high cfm and low static pressure as again, there is no duct. The result is consistent temperature and humidity levels throughout the space, wall to wall and floor to ceiling. Many consider using rooftop units, but to get a similar temperature profile, low ducts from the ceiling to the floor must be fabricated to pull the air back to the unit and duct distribution is a must. With the sheer size of these spaces, the cooling load can sometimes reach hundreds (or even thousands) of tons, which would typically require a fleet of packaged units scattered across the rooftop. With single-unit capacities as high as 500 tons, ARU’s can provide complete coverage of large spaces with very few pieces of equipment. As a result the installation scope is greatly simplified: fewer utility connections, no big cranes, no roof penetrations, etc. Air Rotation units can be mounted inside or alongside the building. The discharge can be 1 direction or upto 4 way for 360 degree coverage. Keep in mind if cooling is a requirement for an existing space, the Air Rotation would be fine for retrofits, but the walls and ceiling should be looked at for R value. A basic space verses a well insulated space can equate to huge amounts of money in first cost unit sizing as well as operation cost.

In conclusion, just like any space one needs to consider the variables of load, what the HVAC units are being asked of and what kind of flexibility is required.

Learn More:

Gas Detection (required for loading docks, and battery storage for forklifts)